Right Now

Power Supply for Semiconductor Equipment Research:CAGR of 16.52% during the forecast period

QY Research Inc. (Global Market Report Research Publisher) announces the release of 2025 latest report “Power Supply for Semiconductor Equipment- Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”. Based on current situation and impact historical analysis (2020-2024) and forecast calculations (2025-2031), this report provides a comprehensive analysis of the global Wire Drawing Dies market, including market size, share, demand, industry development status, and forecasts for the next few years.

The global market for Power Supply for Semiconductor Equipment was estimated to be worth US$ 1209 million in 2024 and is forecast to a readjusted size of US$ 3364 million by 2031 with a CAGR of 16.5% during the forecast period 2025-2031.

【Get a free sample PDF of this report (Including Full TOC, List of Tables & Figures, Chart)】

https://www.qyresearch.com/reports/4943251/power-supply-for-semiconductor-equipment

Power Supply for Semiconductor Equipment Market Summary

Power supply for semiconductor equipment is a high-precision, high-reliability power supply system designed for semiconductor manufacturing equipment, which is used to provide stable and controllable power for key process links such as wafer processing, lithography, etching, ion implantation, etc. Its core lies in meeting the stringent requirements of semiconductor manufacturing nano-scale technology on power quality, which directly affects chip yield and equipment stability.

According to the new market research report "Global Power Supply for Semiconductor Equipment Market Report 2025-2031", published by QYResearch, the global Power Supply for Semiconductor Equipment market size is projected to grow from USD 1208.91 million in 2024 to USD 3364.26 million by 2031, at a CAGR of 16.52% during the forecast period.

Figure00001. Global Power Supply for Semiconductor Equipment Market Size (US$ Million), 2020-2031

Above data is based on report from QYResearch: Global Power Supply for Semiconductor Equipment Market Report 2025-2031 (published in 2025). If you need the latest data, plaese contact QYResearch.

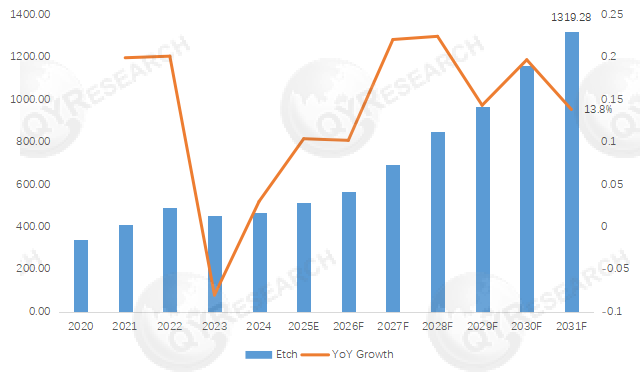

Figure00002. Global Power Supply for Semiconductor Equipment, Market Share of Etch (Ranking is based on the revenue of 2025, continually updated)

Above data is based on report from QYResearch: Global Power Supply for Semiconductor Equipment Market Report 2025-2031 (published in 2025). If you need the latest data, plaese contact QYResearch.

The power supply for semiconductor equipment mainly refers to the core device that provides accurate power for dry etching and wet etching in the etching process, and its core function is to drive the etching reaction through high voltage or high frequency electric field. In dry etching (such as plasma etching), RF power supplies excite reactive gas ionization to form plasma by applying high-frequency electric fields and use high-energy ions to bombard the wafer surface to remove nanoscale materials, and control etching rate, anisotropy and selectivity by adjusting parameters such as power and frequency. At the same time, the DC bias power supply cooperates with the RF power supply to adjust the ion energy and improve the aspect ratio etching accuracy. In wet etching, the electrochemical reaction is driven by high voltage DC power supply, and the etching depth and uniformity are precisely controlled by adjusting the voltage/current density. Both types of power supply must meet the voltage stability, microsecond response speed and impedance matching accuracy to ensure plasma stability and etching yield. Current technology trends include all-solid-state RF power alternatives to tube solutions, GaN/SiC devices to improve efficiency, and pulse modulation techniques to optimize plasma control.

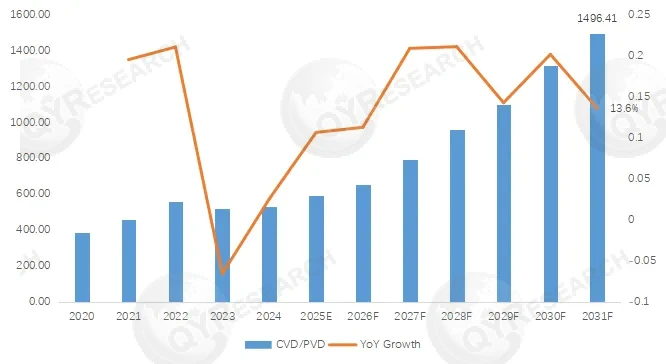

Figure00003. Power Supply for Semiconductor Equipment, Market Share of CVD/PVD

Based on or includes research from QYResearch: Global Power Supply for Semiconductor Equipment Market Report 2025-2031.

Power supply for semiconductor equipment is a key device to provide accurate and stable power for core equipment in CVD (Chemical Vapor Deposition) and PVD (Physical Vapor Deposition) processes. Its core function is to drive plasma generation and material deposition through high voltage, high frequency or DC to ensure film uniformity, density and process controllability.

In the PVD process, a DC or intermediate frequency power supply applies a negative voltage to the sputtering target to excite argon gas to ionize to form a plasma, causing target atoms to sputter and deposit on the substrate surface to form a metal or compound film. For example, magnetron sputtering relies on intermediate frequency power supply to suppress target "poisoning" and arc ignition, improve coating efficiency and film adhesion; multi-arc ion plating requires high-frequency inverter power supply to achieve microsecond arc extinguishing detection and arc stabilization control to ensure film finish.

In CVD process, RF power ionizes reactive gases through high frequency electric field to generate active plasma to promote decomposition of gaseous precursors and deposit dielectric or semiconductor films on substrate surfaces. Plasma enhanced chemical vapor deposition requires ultra-high precision of RF power supply to control the stress and thickness uniformity of silicon nitride film; while in the production of high purity polysilicon, high voltage DC power supply is used for silicon core breakdown, and the power regulation system adjusts the deposition temperature through U/I curve closed-loop, which directly affects the compactness of silicon rod.

Both types of power supplies are required to meet microsecond response, low ripple, and high stability to meet semiconductor manufacturing nanoscale accuracy and yield requirements. Current technology trends focus on wide band gap semiconductor devices and intelligent control, promoting domestic substitution to accelerate breakthrough.

The power supply for semiconductor equipment is the core system that provides accurate power for ion implanters in ion implantation processes, mainly including RF power supply, whose core function is to accelerate ion beam flow through high voltage, accurately control implantation energy and dose, and drive plasma to generate doped ions. In specific applications, high-voltage power supplies provide megavolt DC electric fields for accelerating tubes, accurately control ion energy, and directly affect implantation depth and concentration distribution; RF power supplies are used for ion sources, ionizing gases through high-frequency electric fields to generate boron, phosphorus and other doped ions, and adjusting plasma density in real time to stabilize beam intensity. The two types of power supplies need to meet extreme stability, microsecond response and anti-strike shock capability to ensure implant dose uniformity and wafer yield. At the same time, intelligent power supply integrated AI algorithm can dynamically optimize energy and beam parameters to adapt to the special process requirements of the third generation semiconductor materials.

The power supply for semiconductor equipment mainly refers to a special device that provides high-precision electrical energy for wafer cleaning in the cleaning equipment process. Its core function is to drive physical/chemical reactions through high frequency or high voltage electric fields to remove nano-scale pollutants on the wafer surface and ensure chip manufacturing yield. In specific applications, the megasonic power supply generates cavitation microbubbles in the cleaning solution through high-frequency vibration and removes submicron particles by cavitation effect. The cleaning precision is high, and it is suitable for non-destructive cleaning of deep holes and blind hole structures in high-end processes; the high-voltage DC power supply generates strong electric field in dry cleaning through electrostatic adsorption principle, effectively reducing the use of chemical solvents. The two types of power supplies need to meet frequency stability, continuous power adjustability and anti-interference capabilities to cope with complex process environments. The current technology trend focuses on high frequency and intelligence and promotes the replacement and acceleration of domestic cleaning equipment.

In addition to the above main application areas, power supplies for semiconductor equipment are also widely used in other aspects, such as integrated circuits, advanced packaging, semiconductor displays, semiconductor lighting, etc.

Integrated circuit manufacturing: deep ultraviolet (DUV) or extreme ultraviolet (EUV) light source driving for lithography machine to ensure exposure accuracy; in etching process, high frequency pulse power supply accurately controls plasma density and energy by adjusting pulse width/frequency to achieve high aspect ratio etching; ion implantation link relies on high voltage power supply to accelerate doped ions and control implantation depth and concentration. In film deposition, RF power or IF power excites plasma to promote uniform deposition of dielectric/metal films.

Advanced packaging: Electrolytic copper foil power supply provides uniform current density for copper pillar bump and silicon through hole plating to ensure uniformity of copper layer thickness and interface bonding strength; high voltage DC power supply also drives wire bonding machines, testing machines and other equipment to improve packaging efficiency and reliability.

Semiconductor display: power drives deposition and etching of thin film transistor arrays, and provides stable bias voltage for OLED evaporation equipment to ensure pixel uniformity and panel brightness consistency.

Semiconductor lighting: mainly used for metal organic chemical vapor deposition equipment of LED epitaxial wafer, accurately controlling ionization of reaction gas and film growth, affecting luminous efficiency and wavelength stability.

The report provides a detailed analysis of the market size, growth potential, and key trends for each segment. Through detailed analysis, industry players can identify profit opportunities, develop strategies for specific customer segments, and allocate resources effectively.

The Power Supply for Semiconductor Equipment market is segmented as below:

By Company

Advanced Energy

MKS Instruments

COMET

DAIHEN Corporation

TRUMPF

Shenzhen Hengyunchang Vacuum Technology Co., Ltd.

Kyosan Electric Manufacturing Co., Ltd.

ULVAC

ADTEC Plasma Technology Co., Ltd.

XP Power

Beijing Huacheng Electronics Co., Ltd.

JEOL

ASE Group

Seren IPS

Shenzhen Guangnengda Semiconductor Technology

Shanghai Yianaier Semiconductor Technology Co., Ltd.

Sichuan Yingjie Electric Co., Ltd.

GZR Technology Co., Ltd.

New Power Plasma

Pearl Kogyo Co., Ltd.

Youngsin RF Co., Ltd.

Foy Technology (Foshan)

RF Power Tech

EQ Global

Coaxis Power Systems

Segment by Type

RF Power Supply

DC Power Supply

Segment by Application

Etching

CVD/PVD

Ion Implantation

Cleaning Equipment

Others

Each chapter of the report provides detailed information for readers to further understand the Power Supply for Semiconductor Equipment market:

Chapter 1: Introduces the report scope of the Power Supply for Semiconductor Equipment report, global total market size (valve, volume and price). This chapter also provides the market dynamics, latest developments of the market, the driving factors and restrictive factors of the market, the challenges and risks faced by manufacturers in the industry, and the analysis of relevant policies in the industry. (2020-2031)

Chapter 2: Detailed analysis of Power Supply for Semiconductor Equipment manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc. (2020-2025)

Chapter 3: Provides the analysis of various Power Supply for Semiconductor Equipment market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments. (2020-2031)

Chapter 4: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.(2020-2031)

Chapter 5: Sales, revenue of Power Supply for Semiconductor Equipment in regional level. It provides a quantitative analysis of the market size and development potential of each region and introduces the market development, future development prospects, market space, and market size of each country in the world..(2020-2031)

Chapter 6: Sales, revenue of Power Supply for Semiconductor Equipment in country level. It provides sigmate data by Type, and by Application for each country/region.(2020-2031)

Chapter 7: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc. (2020-2025)

Chapter 8: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 9: Conclusion.

Benefits of purchasing QYResearch report:

Competitive Analysis: QYResearch provides in-depth Power Supply for Semiconductor Equipment competitive analysis, including information on key company profiles, new entrants, acquisitions, mergers, large market shear, opportunities, and challenges. These analyses provide clients with a comprehensive understanding of market conditions and competitive dynamics, enabling them to develop effective market strategies and maintain their competitive edge.

Industry Analysis: QYResearch provides Power Supply for Semiconductor Equipment comprehensive industry data and trend analysis, including raw material analysis, market application analysis, product type analysis, market demand analysis, market supply analysis, downstream market analysis, and supply chain analysis.

and trend analysis. These analyses help clients understand the direction of industry development and make informed business decisions.

Market Size: QYResearch provides Power Supply for Semiconductor Equipment market size analysis, including capacity, production, sales, production value, price, cost, and profit analysis. This data helps clients understand market size and development potential, and is an important reference for business development.

Other relevant reports of QYResearch:

Global Power Supply for Semiconductor Equipment Sales Market Report, Competitive Analysis and Regional Opportunities 2025-2031

Global Power Supply for Semiconductor Equipment Market Outlook, In‑Depth Analysis & Forecast to 2031

Global Power Supply for Semiconductor Equipment Market Research Report 2025

Power Supply for Semiconductor Equipment- Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031

About Us:

QYResearch founded in California, USA in 2007, which is a leading global market research and consulting company. Our primary business include market research reports, custom reports, commissioned research, IPO consultancy, business plans, etc. With over 18 years of experience and a dedicated research team, we are well placed to provide useful information and data for your business, and we have established offices in 7 countries (include United States, Germany, Switzerland, Japan, Korea, China and India) and business partners in over 30 countries. We have provided industrial information services to more than 60,000 companies in over the world.

Contact Us:

If you have any queries regarding this report or if you would like further information, please contact us:

QY Research Inc.

Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United States

EN: https://www.qyresearch.com

Email: global@qyresearch.com

Tel: 001-626-842-1666(US)

JP: https://www.qyresearch.co.jp

More Posts

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.