Right Now

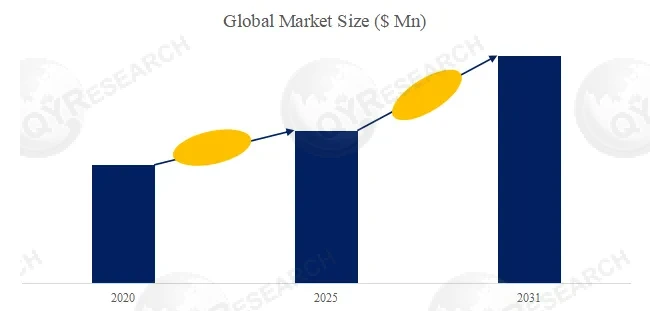

Magnetic Leakage Detector for Tank and Pipe Research Report:the market size is projected to reach USD 0.23 billion by 2031

Magnetic leakage testing (MFL) is one of the commonly used surface defect detection methods for ferromagnetic material products. It is an electromagnetic non-destructive testing method used to detect surface corrosion, pits, grooves, cracks, and other defects of ferromagnetic materials. It has been widely used in the detection of large atmospheric pressure storage tanks, pressure pipelines, components, and steel wire ropes. Magnetic flux leakage detector is a non-destructive testing equipment used to detect surface or near surface defects of metal materials. It helps identify potential defects or damages by measuring changes in the magnetic field, ensuring the safety and normal operation of the equipment. The magnetic leakage detector for storage tanks and pipelines is mainly used to detect defects such as corrosion, cracks, and wall thickness reduction in ferromagnetic materials such as tank bottom plates and pipelines. The principle is based on magnetizing the measured object and capturing the leakage magnetic field signal through sensors, and then analyzing the location and size of defects.

The core technology of the leakage magnetic detector requires high accuracy and high sensitivity, especially in complex environments, such as high temperature, humidity or strong magnetic fields, the stability and accuracy of the equipment are easily affected. How to improve the detection capabilities of equipment, especially in extreme environments, is still a difficult point in technology research and development.

The detection depth and range of magnetic leakage detection technology are limited by the performance of the equipment itself. Existing equipment may find it difficult to provide sufficient accuracy and reliability in the detection of certain specific materials or thicknesses. How to break through technical bottlenecks and achieve deeper and wider range of non-destructive testing is a major challenge facing the industry.

With the development of Industry 4.0 and artificial intelligence technology, leakage magnetic detectors will develop in the direction of intelligence. Future leakage detectors will not only complete detection through manual manipulation, but will also integrate more intelligent analysis and decision-making functions. For example, the detection data is automatically analyzed and processed through built-in AI algorithms to identify potential defects and provide optimization suggestions.

Traditional magnetic leakage detection may require manual participation, but the degree of automation will gradually increase. For example, automated inspection, data collection, analysis and report generation can significantly improve work efficiency, reduce human intervention, and improve the accuracy and real-timeness of detection.

According to the new market research report “Magnetic Leakage Detector for Tank and Pipe - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”, published by QYResearch, the global Magnetic Leakage Detector for Tank and Pipe market size is projected to reach USD 0.23 billion by 2031, at a CAGR of 7.2% during the forecast period.

Figure00001. Global Magnetic Leakage Detector for Tank and Pipe Market Size (US$ Million), 2020-2031

Source: QYResearch, "Magnetic Leakage Detector for Tank and Pipe - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

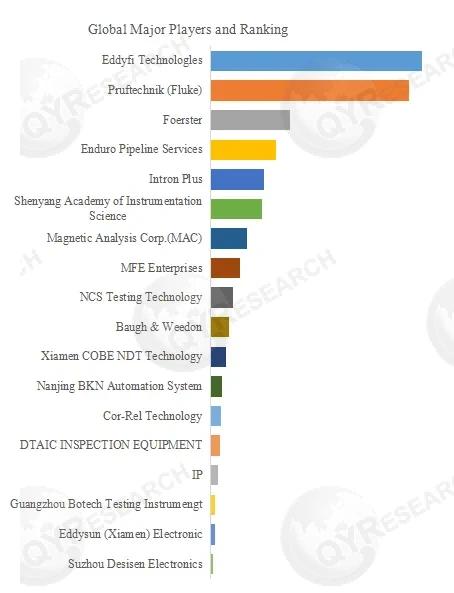

Figure00002. Global Magnetic Leakage Detector for Tank and Pipe Top 18 Players Ranking and Market Share (Ranking is based on the revenue of 2024, continually updated)

Source: QYResearch, "Magnetic Leakage Detector for Tank and Pipe - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

According to QYResearch Top Players Research Center, the global key manufacturers of Magnetic Leakage Detector for Tank and Pipe include Eddyfi Technologles, Pruftechnik (Fluke), Foerster, Enduro Pipeline Services, Intron Plus, Shenyang Academy of Instrumentation Science, Magnetic Analysis Corp.(MAC), MFE Enterprises, NCS Testing Technology, Baugh & Weedon, etc. In 2024, the global top 10 players had a share approximately 82.0% in terms of revenue.

In terms of product type, currently Portable is the largest segment, hold a share of 32.5%.

In terms of product application, currently Oil and Gas is the largest segment, hold a share of 51.5%.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting (data is widely cited in prospectuses, annual reports and presentations), industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

Contact Us:

If you have any queries regarding this report or if you would like further information, please contact us:

QY Research Inc.

Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United States

E-mail: global@qyresearch.com

Tel: 001-626-842-1666(US) 0086-133 1872 9947(CN)

More Posts

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.