Right Now

Industrial X-ray CoIndustrial X-ray Computed Tomography Research:CAGR of 10.7% during the forecast period

Contact Us:

If you have any queries regarding this report or if you would like further information, please contact us:

QY Research Inc.

Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United States

EN: https://www.qyresearch.com

Email: global@qyresearch.com

Tel: 001-626-842-1666(US)

JP: https://www.qyresearch.co.jpQY Research Inc. (Global Market Report Research Publisher) announces the release of 2025 latest report “Industrial X-Ray Computed Tomography System- Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”. Based on current situation and impact historical analysis (2020-2024) and forecast calculations (2025-2031), this report provides a comprehensive analysis of the global Wire Drawing Dies market, including market size, share, demand, industry development status, and forecasts for the next few years.

The global market for Industrial X-Ray Computed Tomography System was estimated to be worth US$ million in 2024 and is forecast to a readjusted size of US$ million by 2031 with a CAGR of %during the forecast period 2025-2031.

【Get a free sample PDF of this report (Including Full TOC, List of Tables & Figures, Chart)】

https://www.qyresearch.com/reports/4548318/industrial-x-ray-computed-tomography-system

Industrial X-ray Computed Tomography Scanners Market Summary

Industrial X-ray computed tomography (CT) scanners can be used in many fields. Automotive, aerospace, medical technology, electronics, and consumer goods industries all have their own manufacturing processes, each with different potential internal defects that are normally hidden from view. By using X-ray to scan components, entirely new application possibilities emerge, from inspecting internal defects and dimensional metrology of internal structures to analyzing the material texture.

The industrial CT is categorized by type into high energy CT, which exceeds 1 MeV and is suited for large components like engine blocks and turbine blades, and low energy CT, operating in the kV range for smaller parts. Focal sizes further divide systems into Mini-focus, Meso-focus, Micro-focus, and Nano-focus, with smaller spots enabling detailed magnification. These types are defined by their energy levels and applications, from high-energy accelerators to low-energy kV sources, and from powerful Mini-focus to precise Micro-focus tubes.

In terms of application, industrial CT addresses the growing complexity and miniaturization in electronic connector manufacturing by offering fast, accurate, and automated inspection solutions. This technology, leveraging multi-angle readings and 3D point clouds, helps industries like automotive and aerospace detect internal defects, enhance product performance, and ensure high-quality standards. For instance, BMW uses CT for early-stage prototype development and analysis, while the aerospace sector relies on it for non-destructive testing of critical components.

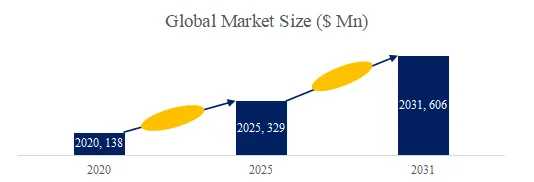

According to the new market research report “Global Industrial X-ray Computed Tomography Market Report 2025-2031”, published by QYResearch, the global Industrial X-ray Computed Tomography market size is projected to reach USD 0.61 billion by 2031, at a CAGR of 10.7% during the forecast period.

Figure00001. Global Industrial X-ray Computed Tomography Scanners Market Size (US$ Million), 2020-2031

Above data is based on report from QYResearch Semiconductor Research Center: Global Industrial X-ray Computed Tomography Scanners Market Report 2025-2031 (published in 2025). If you need the latest data, plaese contact QYResearch.

One of the contributing factors to industrial CT scanning’s growth is how the technology for digital detectors has improved. Not only have digital detectors improved in capturing better image quality, the increase in detector sizes has also allowed manufacturers who produce larger parts to use industrial CT scanning effectively as well. The ability to inspect internal features on a part with various complexities without the need to disassemble the part is one of the biggest contributing factors to why industrial CT scanning’s use is increasing among part manufacturers. Precision measurements are able to be taken with the use of industrial CT scanning services. Even the most minor flaws are able to be identified with 3D imaging, allowing adjustments early in the process of development so that the final product has a higher degree of accuracy and quality. This yields increased customer satisfaction and, ideally, repeat business which is critical for long-term success.

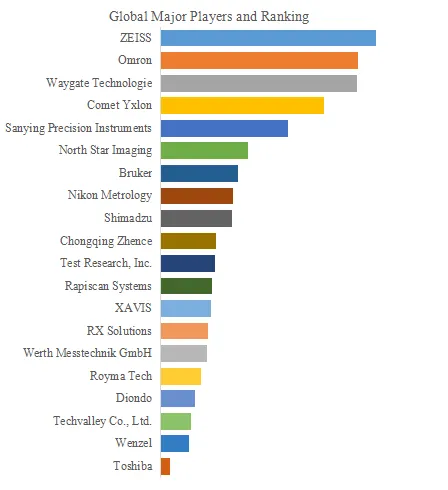

Figure00002. Global Industrial X-ray Computed Tomography Scanners Top 21 Players Ranking and Market Share (Ranking is based on the revenue of 2024, continually updated)

Above data is based on report from QYResearch Semiconductor Research Center: Global Industrial X-ray Computed Tomography Scanners Market Report 2025-2031 (published in 2025). If you need the latest data, plaese contact QYResearch.

Globally, the industrial CT is more concentrated due to its very high technical barriers. According to QYResearch, the global key manufacturers of Industrial X-ray Computed Tomography include ZEISS, Omron, Waygate Technologie, Comet Yxlon, Sanying Precision Instruments, North Star Imaging, Bruker, Nikon Metrology, Shimadzu, Chongqing Zhence, etc. In 2024, the global top 10 players had a share approximately 67.0% in terms of revenue.

These companies have secured significant market shares, driven by their continuous investment in R&D and technological innovation. These leading firms are characterized by their ability to push the boundaries of XCT technology, focusing on enhancing resolution, speeding up scan times, and developing advanced data analysis software. By integrating artificial intelligence and machine learning, they have automated defect detection and analysis, thereby improving inspection efficiency and accuracy. Moreover, these companies are strategically expanding their market presence by diversifying their application areas. While traditional sectors such as aerospace and automotive manufacturing remain core markets, there is a growing trend towards emerging fields like electronics, semiconductors, and additive manufacturing. This diversification strategy not only broadens their customer base but also helps mitigate risks associated with industry-specific downturns.

However, the market is not without its challenges. The balance between high-resolution demands and scan time remains a significant technical hurdle. Additionally, the vast amount of data generated by XCT scans and the computational power required for reconstruction algorithms pose challenges for real-time detection systems. Furthermore, the deep integration of complex materials and multi-modal data necessitates enhanced data processing capabilities. Despite these challenges, the market outlook is promising. The drive towards smart manufacturing and Industry 4.0 continues to fuel the demand for high-precision inspection equipment. The development of new materials and complex processes provides broader application scenarios for XCT technology. Moreover, the gradual improvement of government and industry standards will promote the standardization and mass application of inspection equipment.

Non-destructive testing has now become an indispensable and effective tool in industrial development due to its non-destructive, compatibility, dynamic and rigorous characteristics, reflecting the level of industrial development of a country to a certain extent. X-ray computed tomography (CT), as a non-destructive technology for imaging the internal structure of an object, has undergone significant technical and instrumental development at the turn of the millennium. This has enabled it to be used more importantly outside the medical environment and expanded into the industrial field. Today, CT is an indispensable tool for problem solving, design, improvement and product quality control. At present, the development trend of industrial CT is robotic automated inspection, increasing the resolution to below microns, or using high energy sources (linear accelerators) to inspect large and huge objects. With the advent of the 5G era and the AI era, any industrial equipment combined with AI will burst out with powerful power. With the development of artificial intelligence and big data technology, intelligent CT technology is also emerging. Intelligent CT technology can use deep learning, image processing and other methods to optimize image reconstruction algorithms, improve image analysis capabilities, and realize automatic defect recognition and other functions. Intelligent CT technology can improve detection accuracy and reliability and reduce human errors and interventions.

The report provides a detailed analysis of the market size, growth potential, and key trends for each segment. Through detailed analysis, industry players can identify profit opportunities, develop strategies for specific customer segments, and allocate resources effectively.

The Industrial X-Ray Computed Tomography System market is segmented as below:

By Company

Zeiss

Waygate Technologies

GE

Nikon

Comet Group

Omron

North Star Imaging

Rapiscan Systems

RX Solutions

Shimadzu

Bruker

Toshiba

Viscom AG

VisiConsult

Werth Messtechnik

XAVIS

VJ Technologies

WENZEL

Segment by Type

225 kV

300 kV

450 kV

Segment by Application

Aerospace

Automotive Manufacturing

Electronics and Semiconductors

Others

Each chapter of the report provides detailed information for readers to further understand the Industrial X-Ray Computed Tomography System market:

Chapter 1: Introduces the report scope of the Industrial X-Ray Computed Tomography System report, global total market size (valve, volume and price). This chapter also provides the market dynamics, latest developments of the market, the driving factors and restrictive factors of the market, the challenges and risks faced by manufacturers in the industry, and the analysis of relevant policies in the industry. (2020-2031)

Chapter 2: Detailed analysis of Industrial X-Ray Computed Tomography System manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc. (2020-2025)

Chapter 3: Provides the analysis of various Industrial X-Ray Computed Tomography System market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments. (2020-2031)

Chapter 4: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.(2020-2031)

Chapter 5: Sales, revenue of Industrial X-Ray Computed Tomography System in regional level. It provides a quantitative analysis of the market size and development potential of each region and introduces the market development, future development prospects, market space, and market size of each country in the world..(2020-2031)

Chapter 6: Sales, revenue of Industrial X-Ray Computed Tomography System in country level. It provides sigmate data by Type, and by Application for each country/region.(2020-2031)

Chapter 7: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc. (2020-2025)

Chapter 8: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 9: Conclusion.

Benefits of purchasing QYResearch report:

Competitive Analysis: QYResearch provides in-depth Industrial X-Ray Computed Tomography System competitive analysis, including information on key company profiles, new entrants, acquisitions, mergers, large market shear, opportunities, and challenges. These analyses provide clients with a comprehensive understanding of market conditions and competitive dynamics, enabling them to develop effective market strategies and maintain their competitive edge.

Industry Analysis: QYResearch provides Industrial X-Ray Computed Tomography System comprehensive industry data and trend analysis, including raw material analysis, market application analysis, product type analysis, market demand analysis, market supply analysis, downstream market analysis, and supply chain analysis.

and trend analysis. These analyses help clients understand the direction of industry development and make informed business decisions.

Market Size: QYResearch provides Industrial X-Ray Computed Tomography System market size analysis, including capacity, production, sales, production value, price, cost, and profit analysis. This data helps clients understand market size and development potential, and is an important reference for business development.

Other relevant reports of QYResearch:

Global Industrial X-Ray Computed Tomography System Sales Market Report, Competitive Analysis and Regional Opportunities 2025-2031

Global Industrial X-Ray Computed Tomography System Market Research Report 2025

Global Industrial X-Ray Non-Destructive Computed Tomography System Sales Market Report, Competitive Analysis and Regional Opportunities 2025-2031

Industrial X-Ray Non-Destructive Computed Tomography System - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031

Global Industrial X-Ray Non-Destructive Computed Tomography System Market Research Report 2025

Global and United States Industrial X-Ray Computed Tomography System Market Report & Forecast 2024-2030

Global Industrial X-Ray Computed Tomography System Market Insights, Forecast to 2030

Global Industrial X-Ray Computed Tomography System Market Research Report 2024

Industrial X-Ray Computed Tomography System- Global Market Share and Ranking, Overall Sales and Demand Forecast 2024-2030

Global and United States Industrial X-Ray Non-Destructive Computed Tomography System Market Report & Forecast 2024-2030

Global Industrial X-Ray Non-Destructive Computed Tomography System Market Research Report 2024

Global Industrial X-Ray Non-Destructive Computed Tomography System Market Insights, Forecast to 2030

Industrial X-Ray Non-Destructive Computed Tomography System- Global Market Share and Ranking, Overall Sales and Demand Forecast 2024-2030

About Us:

QYResearch founded in California, USA in 2007, which is a leading global market research and consulting company. Our primary business include market research reports, custom reports, commissioned research, IPO consultancy, business plans, etc. With over 18 years of experience and a dedicated research team, we are well placed to provide useful information and data for your business, and we have established offices in 7 countries (include United States, Germany, Switzerland, Japan, Korea, China and India) and business partners in over 30 countries. We have provided industrial information services to more than 60,000 companies in over the world.mputed Tomography Research:CAGR of 10.7% during the forecast period

More Posts

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.