Right Now

Pre-engineered Modular Pipe Rack Research:CAGR of 5.81% during the forecast period

QY Research Inc. (Global Market Report Research Publisher) announces the release of 2025 latest report “Pre-engineered Modular Pipe Rack- Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”. Based on current situation and impact historical analysis (2020-2024) and forecast calculations (2025-2031), this report provides a comprehensive analysis of the global Wire Drawing Dies market, including market size, share, demand, industry development status, and forecasts for the next few years.

Pre-engineered modular pipe rack is a type of industrial infrastructure that is pre-designed and pre-fabricated off-site, then assembled on-site to support piping systems in a plant or facility. The modular pipe rack typically consists of a series of pre-fabricated steel or aluminum sections that are designed to be bolted or welded together to form a support structure for pipes, valves, and other components. These sections are typically manufactured to standard sizes and configurations, allowing for easy assembly and customization to fit specific site requirements. The benefits of using a pre-engineered modular pipe rack include reduced construction time and costs, increased safety, and improved quality control.

【Get a free sample PDF of this report (Including Full TOC, List of Tables & Figures, Chart)】

https://www.qyresearch.com/reports/2520616/pre-engineered-modular-pipe-rack

Pre-engineered Modular Pipe Rack Market Summary

Pre-engineered modular pipe rack is a type of industrial infrastructure that is pre-designed and pre-fabricated off-site, then assembled on-site to support piping systems in a plant or facility. The modular pipe rack typically consists of a series of pre-fabricated steel or aluminum sections that are designed to be bolted or welded together to form a support structure for pipes, valves, and other components. These sections are typically manufactured to standard sizes and configurations, allowing for easy assembly and customization to fit specific site requirements. The benefits of using a pre-engineered modular pipe rack include reduced construction time and costs, increased safety, and improved quality control.

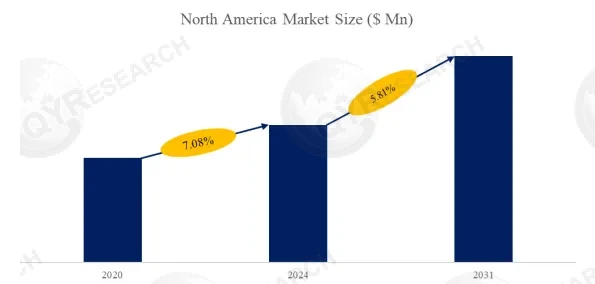

According to the new market research report “North America Pre-engineered Modular Pipe Rack Market Report 2025-2031”, published by QYResearch, the North America Pre-engineered Modular Pipe Rack market size is projected to reach USD 0.23 billion by 2031, at a CAGR of 5.81% during the forecast period.

Figure00001. North America Pre-engineered Modular Pipe Rack Market Size (US$ Million), 2020-2031

Above data is based on report from QYResearch: North America Pre-engineered Modular Pipe Rack Market Report 2025-2031 (published in 2024). If you need the latest data, plaese contact QYResearch.

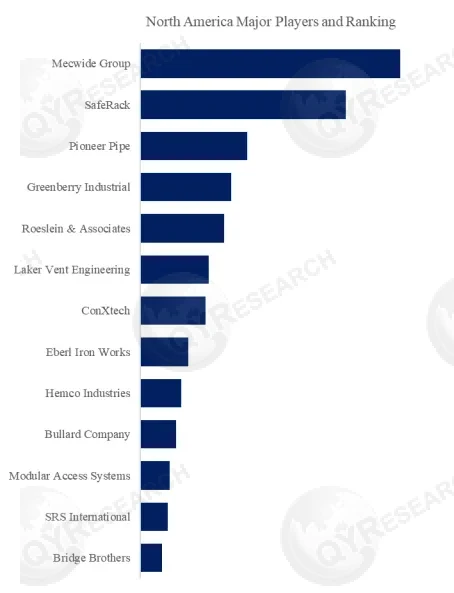

Figure00002. North America Pre-engineered Modular Pipe Rack Top 5 Players Ranking and Market Share (Ranking is based on the revenue of 2024, continually updated)

Above data is based on report from QYResearch: North America Pre-engineered Modular Pipe Rack Market Report 2025-2031 (published in 2024). If you need the latest data, plaese contact QYResearch.

According to QYResearch Top Players Research Center, the North America key manufacturers of Pre-engineered Modular Pipe Rack include Mecwide Group, SafeRack, Pioneer Pipe, Greenberry Industrial, Roeslein & Associates, Laker Vent Engineering, ConXtech, Eberl Iron Works, Hemco Industries, etc. In 2024, the North America top five players had a share approximately 43.8% in terms of revenue.

Pre-engineered Modular Pipe Rack Market Opportunities & Trends in North America Market

Rising Adoption of Modular Construction Methods: Modular construction is increasingly preferred in large industrial and infrastructure projects due to its advantages in cost, time savings, safety, and quality control. Pre-engineered pipe racks fit perfectly into this paradigm by enabling offsite prefabrication and rapid onsite assembly.

Boom in Energy Infrastructure Projects: Global investments in energy transition—including LNG export terminals, hydrogen generation plants, combined-cycle power plants, and nuclear modernization—require large volumes of piping and cable support structures. Modular racks offer scalable and efficient deployment for such projects.

Retrofitting and Brownfield Expansion: In aging facilities where space is limited and shutdowns are costly, modular pipe racks allow for faster installation with minimal disruption to operations. This makes them an attractive solution for brownfield upgrades in refineries, power plants, and chemical facilities.

Digital Engineering Integration (BIM, 3D CAD): The integration of advanced digital tools such as Building Information Modeling (BIM), 3D CAD, and digital twins enhances coordination between stakeholders, reduces rework, and ensures dimensional accuracy. This trend supports the modularization of complex pipe routing layouts.

Pre-engineered Modular Pipe Rack Market Drivers in North America Market

Accelerated Infrastructure Development: The global urbanization and industrialization process is accelerating, driving the demand for piping systems in heavy industries such as electricity, petrochemicals, steel, cement, etc. Pre-engineered modular pipe racks have become the core support structure for large infrastructure projects (such as power plants, refineries, and chemical plants) due to their standardized design and rapid deployment capabilities, and the market demand has increased significantly.

Expansion of the Energy Sector: Traditional Energy: Global expansion of oil & gas pipeline networks (e.g., cross-regional crude oil pipelines, LNG terminals) requires corrosion-resistant, high-strength pipe rack support systems.

Renewable Energy: Wind farms (onshore and offshore), solar power plants, and other clean energy projects are driving demand for modular pipe racks due to their adaptability to complex terrains and shortened installation cycles.

Cost Efficiency Advantages: Prefabrication Cost Reduction: Factory prefabrication lowers on-site labor, equipment rental, and delay-related costs, particularly for budget-sensitive projects.

Economies of Scale: Standardized modular production reduces per-unit costs through large-scale manufacturing, offering price advantages over traditional custom pipe racks.

Lifecycle Economics: High durability and low maintenance requirements of modular pipe racks significantly lower total cost of ownership (TCO) over time.

Pre-engineered Modular Pipe Rack Market Restraints in North America Market

Logistical Complexity for Large Modules: Transporting large and heavy pre-engineered modules requires specialized logistics planning, heavy-lift equipment, and clearance management. In regions with poor transport infrastructure, narrow roads, or regulatory barriers, this significantly increases both delivery time and cost.

Vulnerability to Raw Material Price Volatility: Fluctuations in steel, aluminum, and composite material prices directly impact production costs. Sudden spikes (e.g., due to geopolitical tensions or supply chain disruptions) can erode profit margins or force price increases, reducing competitiveness.

Limited Customization Flexibility: While modular systems offer standardization and speed, they may struggle to accommodate unique architectural layouts, irregular site geometries, or legacy system integration. As a result, some end users prefer traditional construction methods that allow full customization.

Regulatory and Code Compliance Variability: Different countries or regions often enforce varying structural, seismic, fire safety, and environmental standards. Modular designs must be adapted case-by-case, adding engineering burden, certification delays, and limiting cross-border product uniformity.

The report provides a detailed analysis of the market size, growth potential, and key trends for each segment. Through detailed analysis, industry players can identify profit opportunities, develop strategies for specific customer segments, and allocate resources effectively.

The Pre-engineered Modular Pipe Rack market is segmented as below:

By Company

Bridge Brothers

ConXtech

SafeRack

Bullard Company

EPIC Process Systems

Hemco Industries

Greenberry

SRS INTERNATIONAL

Laker Vent Engineering

Epic Systems

Segment by Type

Aluminum Pipe Rack

Steel Pipe Rack

Others

Segment by Application

Power Generation

Oil and Gas

Chemical

Others

Each chapter of the report provides detailed information for readers to further understand the Pre-engineered Modular Pipe Rack market:

Chapter 1: Introduces the report scope of the Pre-engineered Modular Pipe Rack report, global total market size (valve, volume and price). This chapter also provides the market dynamics, latest developments of the market, the driving factors and restrictive factors of the market, the challenges and risks faced by manufacturers in the industry, and the analysis of relevant policies in the industry. (2020-2031)

Chapter 2: Detailed analysis of Pre-engineered Modular Pipe Rack manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc. (2020-2025)

Chapter 3: Provides the analysis of various Pre-engineered Modular Pipe Rack market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments. (2020-2031)

Chapter 4: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.(2020-2031)

Chapter 5: Sales, revenue of Pre-engineered Modular Pipe Rack in regional level. It provides a quantitative analysis of the market size and development potential of each region and introduces the market development, future development prospects, market space, and market size of each country in the world..(2020-2031)

Chapter 6: Sales, revenue of Pre-engineered Modular Pipe Rack in country level. It provides sigmate data by Type, and by Application for each country/region.(2020-2031)

Chapter 7: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc. (2020-2025)

Chapter 8: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 9: Conclusion.

Benefits of purchasing QYResearch report:

Competitive Analysis: QYResearch provides in-depth Pre-engineered Modular Pipe Rack competitive analysis, including information on key company profiles, new entrants, acquisitions, mergers, large market shear, opportunities, and challenges. These analyses provide clients with a comprehensive understanding of market conditions and competitive dynamics, enabling them to develop effective market strategies and maintain their competitive edge.

Industry Analysis: QYResearch provides Pre-engineered Modular Pipe Rack comprehensive industry data and trend analysis, including raw material analysis, market application analysis, product type analysis, market demand analysis, market supply analysis, downstream market analysis, and supply chain analysis.

and trend analysis. These analyses help clients understand the direction of industry development and make informed business decisions.

Market Size: QYResearch provides Pre-engineered Modular Pipe Rack market size analysis, including capacity, production, sales, production value, price, cost, and profit analysis. This data helps clients understand market size and development potential, and is an important reference for business development.

Other relevant reports of QYResearch:

Global Pre-engineered Modular Pipe Rack Market Research Report 2025

Global Pre-engineered Modular Pipe Rack Sales Market Report, Competitive Analysis and Regional Opportunities 2025-2031

Pre-engineered Modular Pipe Rack- Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031

Global Pre-engineered Modular Pipe Rack Market Insights, Forecast to 2030

Global Pre-engineered Modular Pipe Rack Market Research Report 2024

Pre-engineered Modular Pipe Rack - Global Market Insights and Sales Trends 2024

Global Pre-engineered Modular Pipe Rack Market Report, History and Forecast 2018-2029, Breakdown Data by Manufacturers, Key Regions, Types and Application

Global Pre-engineered Modular Pipe Rack Market Insights, Forecast to 2029

Global Pre-engineered Modular Pipe Rack Market Research Report 2023

Global and United States Pre-engineered Modular Pipe Rack Market Report & Forecast 2023-2029

About Us:

QYResearch founded in California, USA in 2007, which is a leading global market research and consulting company. Our primary business include market research reports, custom reports, commissioned research, IPO consultancy, business plans, etc. With over 18 years of experience and a dedicated research team, we are well placed to provide useful information and data for your business, and we have established offices in 7 countries (include United States, Germany, Switzerland, Japan, Korea, China and India) and business partners in over 30 countries. We have provided industrial information services to more than 60,000 companies in over the world.

Contact Us:

If you have any queries regarding this report or if you would like further information, please contact us:

QY Research Inc.

Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United States

EN: https://www.qyresearch.com

Email: global@qyresearch.com

Tel: 001-626-842-1666(US)

JP: https://www.qyresearch.co.jp

More Posts

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.