Right Now

Artillery Shells Analysis Report :the market size is projected to reach USD 4.08 billion by 2031

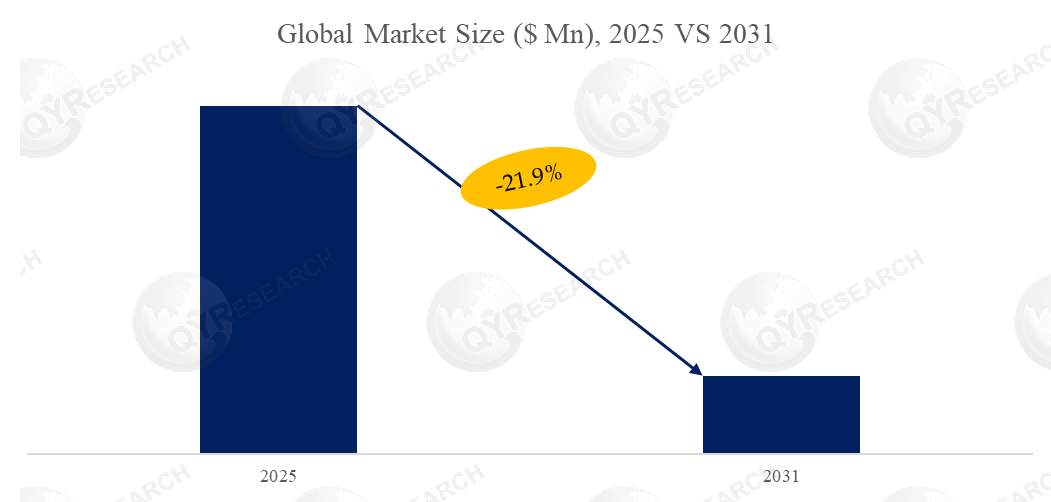

According to the new market research report “Artillery Shells - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”, published by QYResearch, the global Artillery Shells market size is projected to reach USD 4.08 billion by 2031, at a CAGR of -21.9% during the forecast period.

Figure00001. Global Artillery Shells Market Size (US$ Million), 2020-2031

Source: QYResearch, "Artillery Shells - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

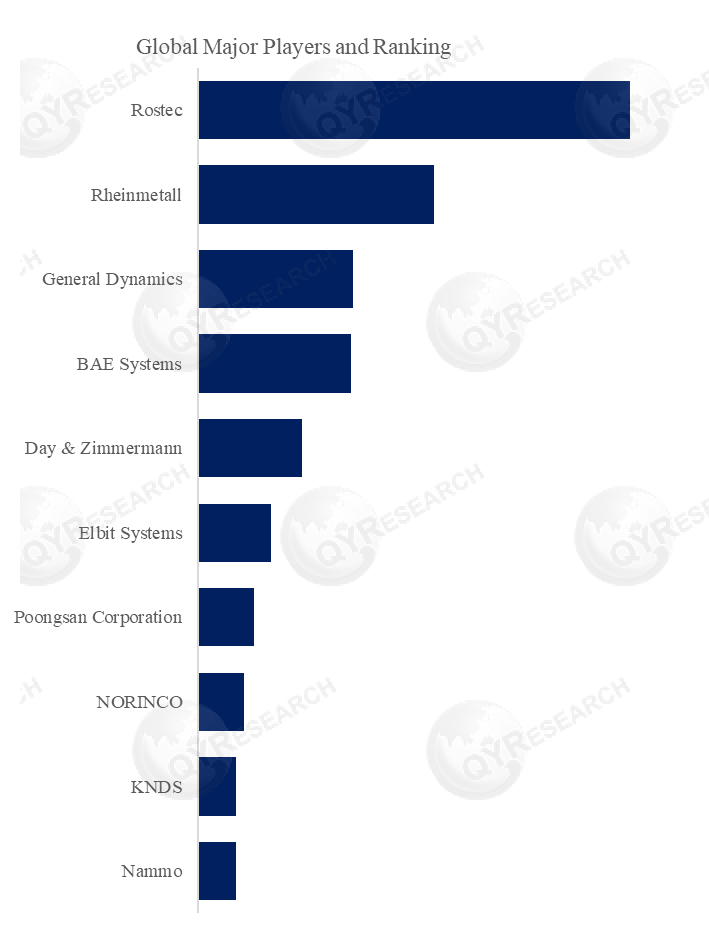

Figure00002. Global Artillery Shells Top 10 Players Ranking and Market Share (Ranking is based on the revenue of 2024, continually updated)

Source: QYResearch, "Artillery Shells - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

According to QYResearch Top Players Research Center, the global key manufacturers of Artillery Shells include Rostec, Rheinmetall, General Dynamics, BAE Systems, Day & Zimmermann, Elbit Systems, Poongsan Corporation, NORINCO, KNDS, Nammo, etc. In 2024, the global top 10 players had a share approximately 79.0% in terms of revenue.

In terms of product type, currently 155mm is the largest segment, hold a share of 48.6%.

In terms of product application, currently High-Explosive (HE) is the largest segment, hold a share of 93.7%.

Market Drivers:

Army incorporates lessons from Russia-Ukraine war in its artillery doctrines, procurement plans. A judicious mix of rockets and guns in the Army’s artillery inventory, to acquire more precision targeting weapon systems and niche technologies and the criticality of a robust battlefield transparency are among lessons from the war.

Heightened geopolitical tensions and military conflicts such as Russian-Ukrainian conflict, Palestinian-Israeli conflict around the world drive demand for military propellants and explosives. Countries increase their defense spending and procure advanced munitions to strengthen their national security and deter potential adversaries.

Military forces are investing in long-range artillery systems capable of striking targets at extended distances. This trend reflects the emphasis on expeditionary warfare and the need to engage adversaries across vast operational theaters.

Restraint:

The global supply chain for Artillery Shells is susceptible to disruptions, including geopolitical tensions, trade restrictions, natural disasters, and cybersecurity threats. Ensuring supply chain resilience and continuity of operations is crucial for meeting defense requirements and maintaining national security.

Since the Russia-Ukraine conflict, artillery consumption has increased rapidly. The cost of raw materials used in propellants and explosives, such as Nitrocellulose, has been increasing since Russia-Ukraine Conflict. Price volatility in raw materials can lead to cost increases for artillery manufacturers and buyers.

Political tensions, conflicts, and territorial disputes in various regions can disrupt supply chains, impede market access, and create uncertainty for defense industry stakeholders. Geopolitical instability also influences defense procurement decisions and strategic partnerships.

Opportunity:

The drive for increased sovereign ammunition manufacturing requirements can be attributed to the demand for artillery platforms, driven in part by the ongoing Ukraine-Russia war where the use of the capability has had a defining impact on the battlefield. More so than any other munition or weapon system, the provision of artillery ammunition and platforms is seen as a key capability.

There's a growing emphasis on developing and deploying artillery shells equipped with precision guidance systems. This trend aims to improve accuracy, reduce collateral damage, and enhance the effectiveness of artillery strikes.

With the proliferation of unmanned aerial systems (UAS), there's a growing demand for artillery shells equipped with non-lethal and counter-UAS capabilities. These munitions can disrupt or neutralize hostile drones while minimizing the risk of collateral damage.

About The Authors

Lu Jing - Lead Author |

Email: lujing@qyresearch.com |

Lu Jing is a technology & market senior analyst specializing in chemical, advanced material, and component. Lu has 10 years’ experience in chemical and focuses on catalyst and additive, metal and plastic materials, waste recycling, daily chemicals. She is engaged in the development of technology and market reports and is also involved in custom projects. |

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

Contact Us:

If you have any queries regarding this report or if you would like further information, please contact us:

QY Research Inc.

Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United States

E-mail: global@qyresearch.com

Tel: 001-626-842-1666(US) 0086-133 1872 9947(CN)

More Posts

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.