Right Now

Global High-Speed Precision CNC Machine Tools Market to Reach USD 27.28 Billion by 2031

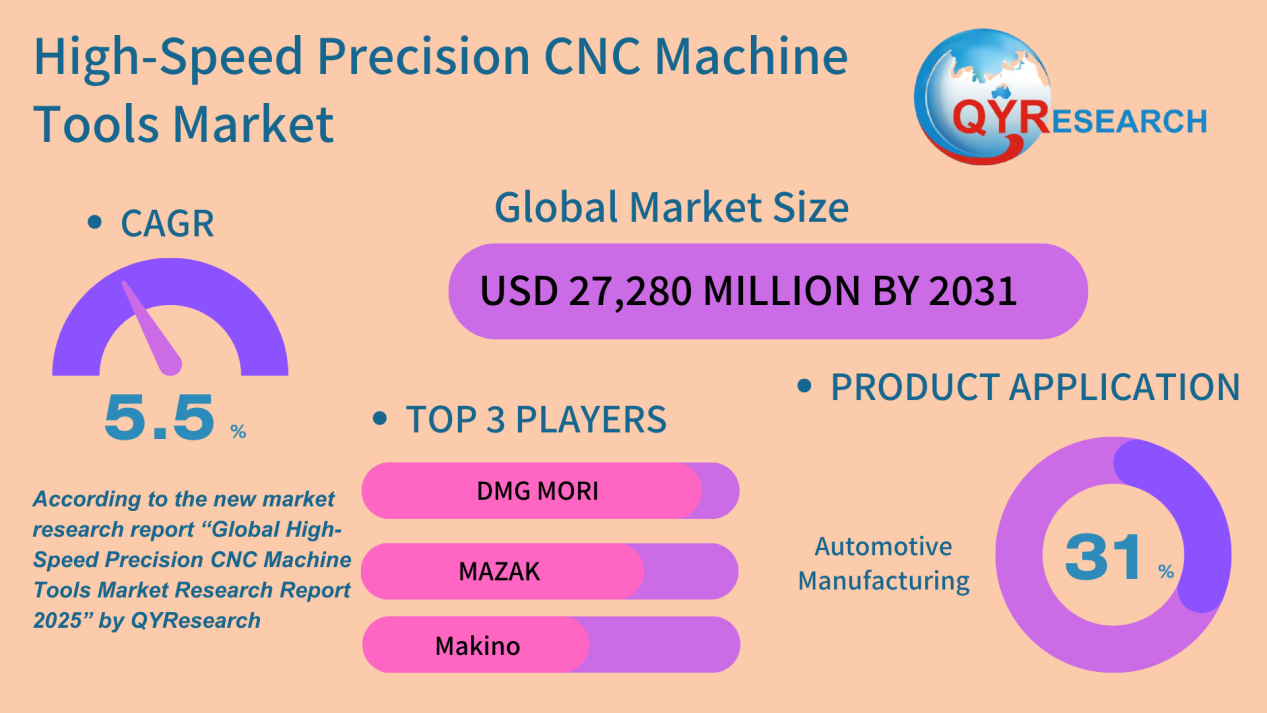

The global market for High-Speed Precision CNC Machine Tools is on a robust growth trajectory, with projections indicating it will rise from USD 18.76 billion in 2024 to USD 27.28 billion by 2031. This growth represents a compound annual growth rate (CAGR) of 5.5% during the forecast period of 2025 to 2031, according to the latest Global Market Research Report 2025 by QYResearch.

Market Trends and Developments in 2025

In 2025, the manufacturing industry is undergoing significant transformations driven by technological advancements and a growing emphasis on sustainability. Key trends include:

1. Integration of Advanced Technologies

Automation and AI-Driven Optimization: Manufacturers are increasingly adopting AI to enhance production efficiency, predictive maintenance, and quality control. AI enables real-time decision-making and reduces downtime.

Digital Twin Solutions: The use of digital twins allows for virtual simulation of manufacturing processes, leading to improved design, monitoring, and optimization of operations.

Edge Computing: Processing data closer to the source enhances real-time analytics and responsiveness in manufacturing systems.

2. Multi-Functional Machine Capabilities

Adaptive Machines: Machines are being designed to handle multiple functions and product variations, enabling mass customization and flexible manufacturing.

Collaborative Robots (Cobots): Cobots work alongside humans, enhancing productivity and safety on the factory floor.

3. Emphasis on Sustainability and Energy Efficiency

Energy-Efficient Machine Designs: Manufacturers are investing in machines that consume less energy and reduce emissions, aligning with environmental regulations and consumer expectations.

Use of Renewable Energy: Integration of renewable energy sources, such as solar and wind, into manufacturing processes is becoming more prevalent.

Circular Economy Practices: Emphasis on recycling, reusing materials, and designing products for longer life cycles to minimize waste.

4. Smart Manufacturing and IoT Integration

IoT-Enabled Systems: Implementation of IoT devices across production lines facilitates real-time monitoring, predictive maintenance, and improved supply chain management.

Data-Driven Decision Making: Analytics derived from IoT data help in optimizing operations and reducing costs.

5. Workforce Development and Skill Enhancement

Upskilling and Reskilling: As automation and AI become more integrated, there is a growing need for workforce training in digital skills and advanced manufacturing technologies.

Human-Machine Collaboration: Emphasis on collaborative environments where humans and machines work together efficiently.

Company Highlights

Leading players driving innovation and market growth include:

DMG MORI

MAZAK

GF Machining Solutions

Makino

Okuma

Haas Automation

Doosan Machine Tools

Hurco Companies

Hermle AG

Chiron Group

FANUC

EMAG GmbH

Hardinge Inc.

Starrag Group

GROB-WERKE GmbH & Co. KG

Among these, Makino has launched a new generation of gantry-type CNC machines in early 2025 with real-time vibration control and enhanced micron-level accuracy, setting a new benchmark in the segment.

Company Product Models Overview

DMG MORI

DMU 50 3rd Generation – 5-axis milling, 15,000 rpm spindle.

NTX 1000 – Turn & mill machine for complex components.

NHX 4000 – Horizontal machining center with pallet automation.

MAZAK

VARIAXIS i-700 – 5-axis simultaneous machining center.

INTEGREX i-200 – Multi-tasking machine with milling and turning.

QUICK TURN 250MY – CNC turning center with milling capability.

GF Machining Solutions

AgieCharmilles CUT P 550 – Wire EDM with high-speed digital generator.

FORM P 350 – Die sinking EDM for mold industries.

MILL P 500 – High-performance 5-axis machining center.

Makino

DA300 – 5-axis vertical machining center for aerospace components.

F5 – High-speed vertical machining for die/mold applications.

a61nx – Horizontal machining center with 14,000 rpm spindle.

Okuma

GENOS M560-V-e – Affordable vertical machining center.

LT2000 EX – 2-turret CNC lathe for high productivity.

MU-6300V – 5-axis machining center with multitasking capability.

Haas Automation

VF-2 – Vertical machining center, 30" x 16" x 20" travel.

ST-20Y – Y-axis CNC turning center with live tooling.

UMC-750 – 5-axis universal machining center.

Doosan Machine Tools

PUMA 2600SY II – CNC turning center with sub-spindle and Y-axis.

VC 630/5AX – 5-axis vertical machining center.

DNM 5700 – Vertical machining center for general purpose use.

Hurco Companies

VMX42i – High-speed vertical machining with WinMax control.

TM8i – CNC turning center with compact footprint.

VCX600i – 5-axis trunnion-style machining center.

Hermle AG

C 250 – Entry-level 5-axis machining center.

C 400 – Precision machining with mineral cast bed.

C 650 – Flexible 5-axis model for larger workpieces.

Chiron Group

FZ 12 FX – Compact vertical machining center.

MT 715 – Turn-mill center with automation interface.

MILL FX 800 – Precision 5-axis machining solution.

Market Segmentation

By Type:

Vertical High-Speed Precision CNC Machine Tools

Horizontal High-Speed Precision CNC Machine Tools

Gantry High-Speed Precision CNC Machine Tools

Multi-Function High-Speed Precision CNC Machine Tools

Others

By Application:

Automotive Manufacturing

Aerospace

Mold Processing

Electronic Equipment

Others

Regional Insights

Asia-Pacific leads the global market with significant investments from China, Japan, and South Korea, driven by growing demand in automotive and electronics manufacturing. Europe and North America continue to invest in high-precision applications, particularly for aerospace and defense.

Challenges and Outlook

While the market outlook is optimistic, challenges remain in the form of high capital investment, skilled labor shortages, and volatility in global trade policies. The U.S. 2025 tariff policies are expected to influence supply chain decisions and regional competitiveness significantly.

Overall, the High-Speed Precision CNC Machine Tools market is expected to maintain its growth momentum, driven by technological advancements, rising end-user demand, and strategic investments by top manufacturers worldwide.

Related Reports:

Global High-Speed Precision CNC Machine Tools Market Research Report 2025

https://www.qyresearch.com/reports/4713873/high-speed-precision-cnc-machine-tools

Global High-Speed Precision CNC Machine Tools Sales Market Report, Competitive Analysis and Regional Opportunities 2025-2031

https://www.qyresearch.com/reports/4713869/high-speed-precision-cnc-machine-tools

Global High-Speed Precision CNC Machine Tools Market Insights, Forecast to 2031

https://www.qyresearch.com/reports/4713868/high-speed-precision-cnc-machine-tools

High-Speed Precision CNC Machine Tools - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031

https://www.qyresearch.com/reports/4713867/high-speed-precision-cnc-machine-tools

About Us

QYResearch founded in California, USA in 2007. It is a leading global market research and consulting company. With over 18 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 66,000 clients across five continents. Let’s work closely with you and build a bold and better future.

Contact Us:

If you have any queries regarding this report or if you would like further information, please contact us:

QY Research Inc.

Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United States

E-mail: global@qyresearch.com

Tel: 001-626-842-1666(US) 0086-133 1872 9947(CN)

EN: https://www.qyresearch.com

JP: https://www.qyresearch.co.jp

More Posts

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.