Right Now

Exactly how does a biomass pellet mill job?

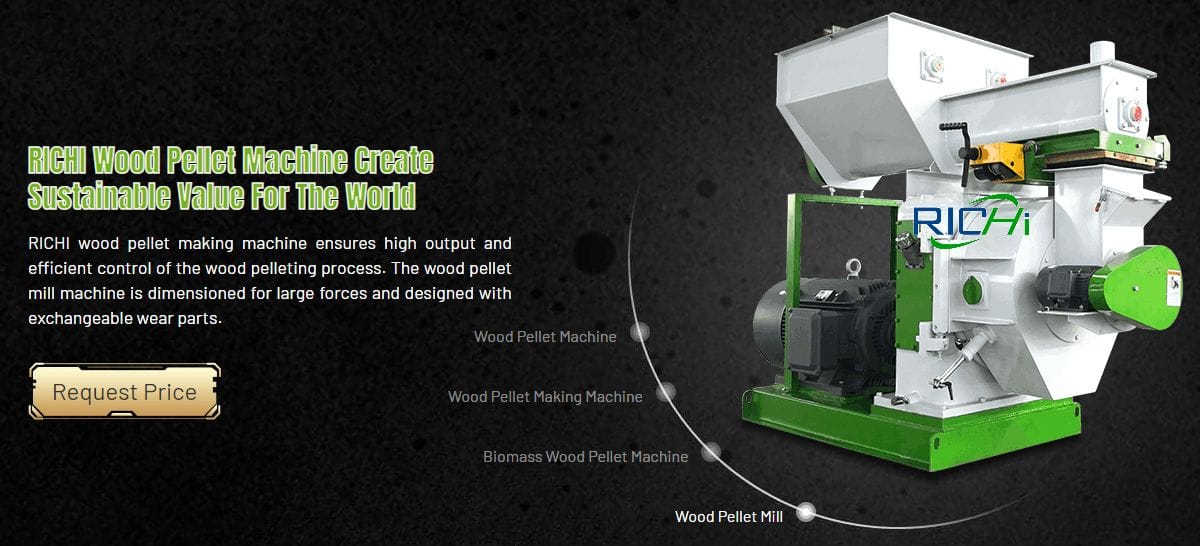

Biomass pellet mills are made use of to produce pellets from biomass materials such as wood, sawdust, straw, and lawns. These pellets are utilized as gas in different applications, consisting of home heating homes as well as companies, generating electricity, and also sustaining commercial processes.

The process of making biomass pellets entails numerous actions. The very first step is to accumulate and refine the raw materials. The raw materials are usually collected in the form of timber chips, sawdust, straw, or various other biomass resources. The raw products are then processed to get rid of any type of impurities, such as rocks or dirt, and also to decrease their size. The size reduction procedure can be done making use of various tools such as chippers, mills, or shredders.

When the raw materials are refined, they are fed into the pellet mill. The pellet mill includes a die and also a set of rollers. The raw products are fed into the mill, where they are pressed by the rollers via the die. The compression process heats the raw products, creating the lignin in the wood to soften and also work as a all-natural binding agent. The warmth likewise decontaminates the product, killing any kind of microorganisms or fungis that may be present.

As the pressed material travels through the die, it develops into cylindrical pellets. The pellets are then reduced to the desired length and also cooled down. The cooling process is necessary to guarantee the pellets are set and maintain their form.

https://www.richipelletmachine.com/hay-pellet-machine-for-sale/

The completed pellets can after that be kept wholesale or nabbed for transport and use. The pellets are normally saved in a dry place, free from wetness as well as exposure to the aspects.

Biomass pellet mills are offered in numerous dimensions as well as abilities. Small mills can produce a few hundred extra pounds of pellets per hour, while larger mills can generate a number of tons per hr. The choice of mill size and capacity depends on the meant use and also the accessibility of basic materials.

One crucial element to think about when making use of biomass pellets as gas is their energy performance. Biomass pellets have a high energy thickness, implying they include a lot of power in a little volume. This makes them an efficient gas resource that can minimize heating and power costs.

An additional important factor to think about is the ecological impact of using biomass pellets. Unlike fossil fuels, which release carbon dioxide and other contaminants when burned, biomass pellets are a renewable energy source that emits much less co2 and also various other contaminants. They also assist to lower waste by utilizing biomass products that would certainly or else be disposed of.

Along with home heating and power applications, biomass pellets are likewise used in pet feed and bed linen, in addition to for food preparation as well as barbecuing. The versatility of biomass pellets makes them a useful commodity in numerous sectors.

In conclusion, biomass pellet mills are an important part of the renewable energy sector. They provide a lasting source of gas that is reliable, economical, and also environmentally friendly. The procedure of making biomass pellets entails gathering as well as processing resources, compressing them into round pellets, and also cooling and saving them for usage. With the boosting need for renewable resource sources, the use of biomass pellets is anticipated to grow, making biomass pellet mills an vital financial investment for the future.

For details please contact: RICHI Official Website

WhatsApp:86 138 3838 9622

Email:enquiry@richipelletmachine.com

More Posts

Richi Machinery

-

Longhai 2nd Rd & 10th St, Kaifeng City, Henan Province, Chin

Zhengzhou, Henan 450001

中国 - 8613838389622

- All day

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.