Right Now

Promising biomass wood pellet mill offer for sale.

The biomass wood pellet mill can collect, dry and also pulverize numerous spread as well as certain shapes of plant straws under a particular temperature and stress as well as extrude them right into routine, dense rod-shaped, block-shaped or granular gas to boost their transportation and also storage space ability. Biomass pellet mill devices are widely utilized due to the fact that they fulfill the requirements of contemporary environmental management and also energy conserving. So, in the current market, what benefits does the biomass timber pellet mill machine have? Richi Machinery, that is focused on the wood pellet mill to buy, has the answer for you now.

1. The timber pelletizer does not require independent lubrication

( 1) The new sort of pressure roller embraces international cutting-edge innovation, advanced technology, and also innovative integrated packaging. Throughout the production process, there is practically no requirement to change the bearing as well as no demand to restore oil.

( 2) The main shaft and also reducer are lubed with thin oil, which efficiently lowers the temperature level of the main shaft bearing as well as does not require completely dry oil lubrication.

Related post: wood pellet making machine

2. The timber pellet mill maker has a strengthened transmission system

( 1) The drive of the biomass wood pellet mill embraces the identical shaft three-stage hard tooth surface area to reduce the teeth, the variety of gears is raised, the equipments are expanded and also enhanced, and the transmission stamina is 3-5 times that of the typical reducer.

( 2) The biomass timber pellet mill takes on high-efficiency and energy-saving motor, plug-in straight connection, high coaxiality, high-speed shaft takes on parallel shaft structure, gear shaft takes on two-point support for turning, high rigidity, steady and also dependable transmission, and also can be updated to a larger one. stamina.

( 3 )The transmission result is integrated with the primary shaft, and also the restricted link form is abandoned, and the stamina is improved.

( 4) The length of the primary shaft is shortened and also the rigidness is significantly boosted, which can properly minimize the wear of the stress roller and the mold.

( 5) The discharge port of the wood pellet mill can be turned at multiple angles, and also the installation is much more flexible.

The above are the main advantages of the biomass timber pellet mill. Through 2 advantages, it brings a great deal of benefit and also technical operation to the biomass timber pellet granulator device.

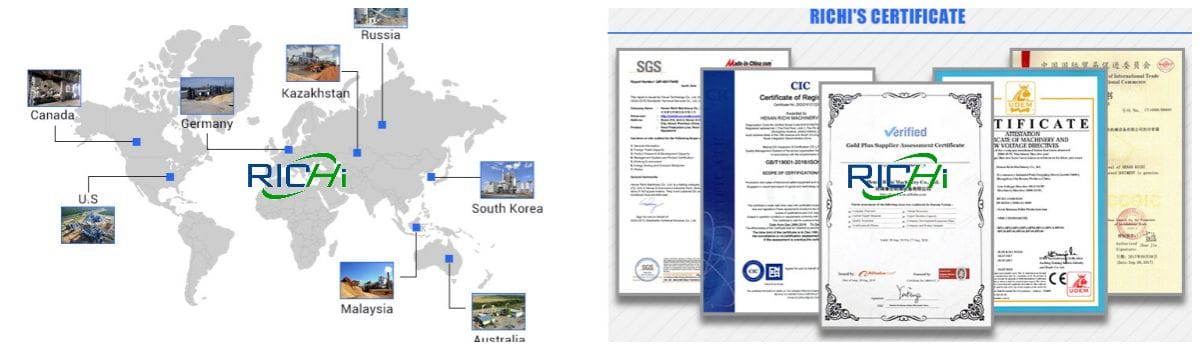

If you need to know even more regarding timber pellet mill to buy Romania, timber pellet mill for sale South Korea, wood pellet mill available Australia, timber pellet mill for sale Indonesia, timber pellet mill available Ukraine, timber pellet mill available Congo, wood pellet mill for sale Netherlands, please contact Richi Machinery for information.

Related post: https://www.richipelletmachine.com/wood-pellet-making-machine-for-sale/

3. Just how to effectively keep the wood pellet mil?

Wood pellet mill offer for sale can be stated to be a really typical mechanical tools in our life. With the raising appeal of environmental management and also power conserving concepts, the application variety of timber pellet manufacturer device is likewise becoming increasingly more comprehensive.

So, how do we properly keep the wood pellet mill and also lengthen its life span?

( 1) Bear in mind not to utilize waste oil straight

After the oil high quality evaluation of the waste oil replaced by the timber pellet mill, corresponding actions are taken, as well as a few of them can be recycled. But we should be careful not to straight include waste oil to the pellet equipment, which will trigger damages to the pellet device as well as reduce its service life.

If you intend to recycle the waste oil of the sawdust wood pellet mill, the water in the oil can be dried out by an oil-water separator; the mechanical pollutants as well as sludge in the oil can be removed by a filter.

( 2) Not all oiling oils are suitable for timber pellet mills

In order to make the devices lubed reasonably in various settings, a certain amount of additives should be included in the lubricating oil. The ingredients included in different lubricating oils are various, and also the efficiency is likewise various. For that reason, according to the tools conditions as well as use. Just by choosing the appropriate lube for the setting can it play a excellent lubricating effect.

( 3) Adding even more oil to the equipment is not the far better

When a wood pellet mill is developed, its refueling amount is strictly defined. The driver needs to add lubricating oil according to the instructions as well as the oil criterion as well as view glass observed daily. If too much oil is added, it will have particular side effects as well as trigger damage to the sawdust wood pellet mill device.

Related post: wood pellet plant

4. Concerning biomass power

Biomass power is a type of renewable energy with a large range of connotations, and the power contained in biomass is called biomass energy.

Currently, the growing location of crops in numerous countries is large, so it is important to create biomass power. Nonetheless, today, the application rate of plant straws is reduced, and also the usage process damages the environment, causing massive waste of biomass power, and likewise destroying the ecological balance. As a result, the reliable use biomass power is of great value to boosting my country's energy application framework, damaging the percentage of fossil energy and also promoting a environment-friendly eco-friendly balance.

The biomass fuel machined by wood pellet mill mainly depends on the lignin in the biomass. When the pressure raises, the pellet characteristics of the lignin itself transform, the pellets deform, as well as plastic circulation is created, the optimum stress and anxiety vertical to the fragment direction is extended, and as the stress progressively boosts, the pellets fill deep spaces with each other, together with a huge quantity of warm generated by the rubbing between journalism roller and the material, and also between the material and the product, the lignin is heated to the softening temperature level (70-100 ℃), the adhesion of the lignin is improved, and also the softened The mixed activity of lignin and also the initial cellulose of the biomass makes the biomass form. More Info

The biomass fuel wood pellet mill makes use of low-cost, easy-to-fetch, as well as otherwise difficult-to-handle plant straws and also farming and also forestry wastes to make biomass briquette fuel. The impact of the dampness web content of the gas as well as the ratio of raw materials on the relaxation thickness, decrease resistance, wetness absorption resistance as well as compressive stamina of the biofuel was further studied, as well as the longevity of the gas was thoroughly assessed.

Richi Equipment is a feed equipment and also wood pellet palnt supplier specializing in the wood pellet mills for sale, if you have an interest in our timber pellet mill tasks and services, please leave your demands as well as e-mail, WhatsApp as well as various other contact details, our sales staff will give professional solutions as well as matching product pictures, video clips as well as quotes.

For details please contact: Pellet mill

WhatsApp:86 138 3838 9622

Email:enquiry@richipelletmachine.com

More Posts

Richi Machinery

-

Longhai 2nd Rd & 10th St, Kaifeng City, Henan Province, Chin

Zhengzhou, Henan 450001

中国 - 8613838389622

- All day

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.