Right Now

Resources requirements for biomass pellet mill?

The biomass pellet mill has basic demands for basic materials in the production procedure. Too great resources will trigger the biomass pellet forming price to be reduced as well as more powdery. The quality of the developed pellets made by biomass pellet mill likewise impacts the production performance as well as power consumption.

Typically speaking, raw materials with tiny pellet dimension are very easy to compress, as well as basic materials with big pellet dimension are more difficult to compress. In addition, the water resistance, hygroscopicity as well as molding density of the raw materials are carefully related to the dimension of the gas pellets made by biomass pellet mill

When the same material with different pellet dimensions is at low pressure, the larger the pellet dimension of the product, the slower the molding thickness changes, however as the stress raises, the distinction becomes less noticeable when the stress gets to a particular worth.

Pellets with a little pellet dimension have a huge details surface, and timber chips are easy to absorb dampness as well as reclaim moisture; on the other hand, since the pellet size of the pellets becomes smaller, the gaps in between pellets are easily filled, as well as the compressibility becomes larger, which makes the residual inner content inside the biomass pellets. The tension lessens, therefore weakening the hydrophilicity of the developed block as well as improving the water resistance.

RICHI concentrates on biomass pellet mill for sale, also focuses on technical advancement and also lasting growth regularly. It rates as one of residential leading manufacturers in research & growth capability, making capacity as well as product top quality.

Related post: alfalfa pellet machine

1. What are the criteria for biomass resources?

What are the standards for resources in the manufacturing of biomass pellet mill? Obviously, there should be a small limitation to the small size. If the pellet size of the wood chips is as well tiny, the common inlaying and also matching capacity of the wood chips will certainly be decreased, causing poor molding or reduced resistance to damaging. For that reason, it is better not to be less than 1mm.

The dimension ought to not exceed the limit. When the pellet size of the wood chips is higher than 5MM, it will increase the friction in between journalism roller and also the unpleasant device, boost the extrusion rubbing of the biomass gas pellet maker, and waste unnecessary energy intake.

Therefore, the production of biomass pellet mill generally requires that the pellet dimension of the raw product be regulated between 1-5mm.

2. Pellet fuel from biomass pellet mill.

Biomass pellet fuel is a sort of eco-friendly brand-new power, which makes use of plant wastes, such as sawdust, branches and also sapwood, corn stover, rice straw and also rice husk, as well as is made right into pellets through the biomass pellet mill and also biomass pellet production line.

Related post: https://www.richipelletmachine.com/alfalfa-pellet-machine-for-sale/

Pellets made by biomass pellets making equipment are fuels for straight combustion, which can indirectly replace coal, oil, electrical energy, natural gas and also various other power resources.

Burning heat loss (Q4) is primarily zero, coal fired heating system Q4 is 7-15%, and also our ST is 0.41 with a big amount of coal, the distinction in SO2 discharges after burning is 20.5 times. Therefore, along with alternative fuels such as coal and oil, biomass pellet gas can reduce air pollution, make SO2 and carbon dioxide harmful gases, and achieve basically no emissions.

Biomass pellet gas made by biomass pellet mill mainly originates from wood processing, forest pruning and also various other wastes as well as plant straw, resources resources are wide, China is abundant in resources, easy to buy production, it is more affordable than coal and also has greater thermal efficiency.

Pellet gas remains in line with my nation's industrial plan as well as our province's total prepare for power preservation as well as exhaust decrease. At the same time, waste recycling can raise farmers' income and work, include brand-new gas to the countryside, and enhance farmers' quality of life.

The biomass pellet fuel processed by the biomass fuel pellet maker additionally has good combustion performance comparable to briquette, and also has the advantages of less sulfur content, less ash material as well as lighter environmental pollution than coal.

Compared with firewood, biomass pellet gas has low water material, high specific gravity as well as high calorific worth, which is beneficial to boost the thermal effectiveness of biomass pellet fuel heating system. For that reason, biomass pellet fuel is extensively made use of in biomass straw nuclear power plant, central heating boilers of ventures and institutions, biomass straw gasification terminals, house stoves, European home heating heaters, and so on, therefore replacing coal as well as solving environmental pollution troubles.

Related post: grass pelletizer

Biomass pellet gas made by biomass pellet mill machine can be utilized in fabric, printing and also dyeing, paper, food, rubber, plastic, chemical, pharmaceutical and other commercial products, and also can be utilized for home heating, bathing, air conditioning as well as day-to-day heating in enterprises, establishments, resorts, colleges, dining establishments, as well as solution industries. water.

Compared to various other production approaches, biomass pellet mill has the features of simple production procedure, straightforward devices, easy procedure, simple to understand industrial manufacturing and large-scale use.

Effective advancement as well as use of strengthened plant straws can change raw coal to properly alleviate energy lacks, control natural waste contamination, shield the ecological atmosphere, and advertise harmony in between man as well as nature.

According to statistics, shedding 10,000 lots of wood pellets as an environmentally friendly gas can change 8,000 tons of conventional coal, and the price proportion is undoubtedly 1:2. Thinking that the conventional coal is exchanged eco-friendly gas wood pellets every year, the rate of using 10,000 tons of pellets will certainly conserve 1.6 million yuan annually compared to coal as well as 1.9 million yuan contrasted to natural gas.

Currently, lots of areas still use natural gas, coal, and so on, where using boilers needs thermal power, the use of wood pellets, an eco-friendly and inexpensive gas, can be advertised. he said

Timber pellets made by biomass granulator mainly make use of farming and forestry wastes such as straw, rice husks, straw, cotton stalks, husks, branches, as well as sawdust as resources, which are processed right into shaped pellet gas as well as applied in numerous sectors. The feature of biomass pellets has also been enhanced. It will increase the bigger advancement and also application areas, as well as promote the biomass pellet mill to have more growth space.

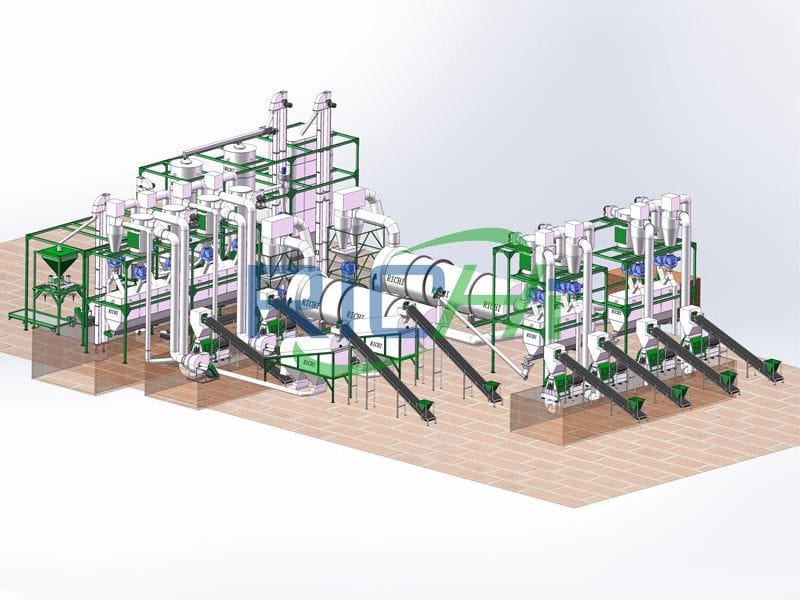

Richi Machinery is an devices supplier concentrating on the biomass pellet mills available for sale

If you need to know more concerning wood biomass pellet mill up for sale Brazil, hot sale 2 load per hr biomass pellet mill offer for sale Romania, dual layer biomass pellet mill available South Korea, ring die sawdust biomass pellet mill up for sale Poland, high performance 160 kw biomass pellet mill for sale United States, biomass pellet mill to buy Austria, biomass pellet mill for sale Australia, please get in touch with Richi Equipment for details.

For details please contact: Pelleting machine

WhatsApp:86 138 3838 9622

Email:enquiry@richipelletmachine.com

More Posts

Richi Machinery

-

Longhai 2nd Rd & 10th St, Kaifeng City, Henan Province, Chin

Zhengzhou, Henan 450001

中国 - 8613838389622

- All day

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.