Right Now

Multi-use Cell Bioreactors and Fermente Market Research: the market size is projected to reach USD 1.45 billion by 2031

Multi-use cell bioreactors and fermenters are traditional and widely used in the bioprocessing industry, having a long history of successful applications. These are robustly constructed with materials like stainless steel or high-quality glass, enabling them to withstand repeated use over extended periods. One of the key benefits of multi-use equipment is its cost-effectiveness in the long run. Although the initial investment may be higher compared to single-use alternatives, the ability to reuse the equipment multiple times significantly reduces the overall cost per production cycle.

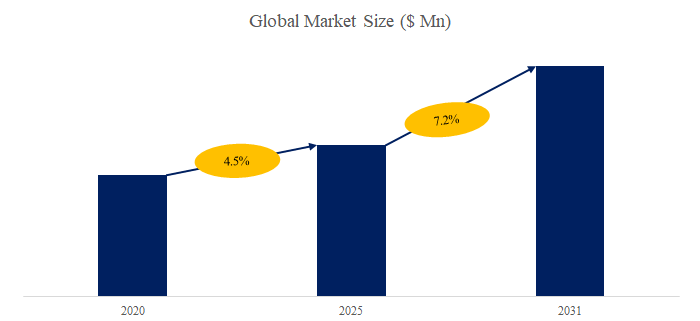

According to the new market research report “Multi-use Cell Bioreactors and Fermenters - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”, published by QYResearch, the global Multi-use Cell Bioreactors and Fermenters market size is projected to reach USD 1.45 billion by 2031, at a CAGR of 7.2% during the forecast period.

Figure00001. Global Multi-use Cell Bioreactors and Fermenters Market Size (US$ Million), 2020-2031

Source: QYResearch, "Multi-use Cell Bioreactors and Fermenters - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

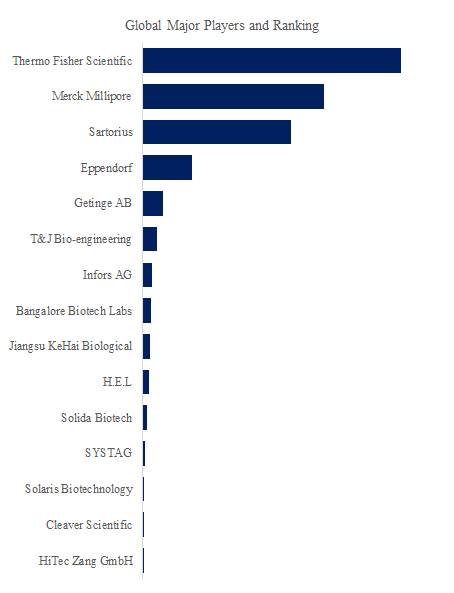

Figure00002. Global Multi-use Cell Bioreactors and Fermenters Top 15 Players Ranking and Market Share (Ranking is based on the revenue of 2024, continually updated)

Source: QYResearch, "Multi-use Cell Bioreactors and Fermenters - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

According to QYResearch Top Players Research Center, the global key manufacturers of Multi-use Cell Bioreactors and Fermenters include Thermo Fisher Scientific, Merck Millipore, Sartorius, Eppendorf, Getinge AB, T&J Bio-engineering, Infors AG, Bangalore Biotech Labs, Jiangsu KeHai Biological, H.E.L, etc. In 2023, the global top five players had a share approximately 68.3% in terms of revenue.

In terms of product type, Floor standing Equipment is the largest segment, hold a share of 54.01% in 2024.

In terms of product application, biopharmaceuticals is the most dominant downstream application, accounting for approximately 73.1% share in 2024.

Market Drivers & Growth Opportunities:

1.Growth of Biopharmaceutical Industry: The increasing prevalence of chronic diseases has led to a growing demand for biopharmaceutical products. Biopharmaceutical companies are constantly expanding their production scale and R&D efforts. Multi - use cell bioreactors and fermenters, which offer high - quality and stable production, are important tools for manufacturing vaccines, antibodies, and other biologics, thus driving the growth of the market.

2.Technological Advancements: Continuous progress in bioreactor technology has improved the performance and reliability of multi - use cell bioreactors and fermenters. For example, the application of advanced control systems such as PLC can precisely control parameters such as temperature, pH, and dissolved oxygen, ensuring the stability and reproducibility of the process. The integration of artificial intelligence and machine learning technologies can also enhance process optimization and real - time data analysis.

3.Cost - effectiveness: Although there is a high initial investment in setting up multi - use bioreactor systems, they can be reused multiple times, which reduces the overall production cost compared to single - use systems. In the case of large - scale production, the cost - saving advantage is more significant, making multi - use cell bioreactors and fermenters more attractive to manufacturers.

Market Challenges & Risks:

1. High Initial Investment and Operational Costs

Multi-use cell bioreactors and fermenters often require a significant upfront investment for purchase, installation, and commissioning. These systems are complex, with advanced control mechanisms, sterilization equipment, and monitoring systems. Additionally, the cost of maintaining and operating them is substantial. Regular cleaning, sterilization using expensive chemicals, and calibration of sensors add to the long-term expenses. For small and medium-sized biotech companies or research institutions with limited budgets, these high costs can be a major deterrent, limiting their ability to invest in such equipment.

2. Stringent Cleaning and Sterilization Requirements

To ensure product quality and avoid contamination, multi-use bioreactors and fermenters must undergo thorough cleaning and sterilization between batches. Meeting these stringent requirements can be challenging and time-consuming. Even minor residues or improper cleaning can lead to cross-contamination, which can have severe consequences for the biopharmaceutical products being manufactured. The need for validated cleaning and sterilization protocols also adds to the regulatory burden and compliance costs for manufacturers.

3. Technological Obsolescence

The biotech and pharmaceutical industries are rapidly evolving, with new technologies emerging constantly. Multi-use cell bioreactors and fermenters need to keep up with these advancements to remain competitive. For example, the development of single-use bioreactors with improved features such as ease of use, reduced risk of contamination, and faster setup times poses a threat to the multi-use systems. If multi-use bioreactor manufacturers fail to innovate and incorporate the latest technologies, their products may become obsolete, leading to a loss of market share.

4. Regulatory Hurdles

The biopharmaceutical industry is highly regulated, and the use of multi-use cell bioreactors and fermenters is subject to strict guidelines. Manufacturers must comply with regulations related to product quality, safety, and traceability. Any deviation from these regulations can result in product recalls, fines, or even the suspension of production. Obtaining regulatory approvals for new processes or modifications to existing multi-use systems can be a complex and time-consuming process, delaying product development and commercialization.

Development trend of Multi-use Cell Bioreactors and Fermenters:

1.Technological innovation

Automation and intelligent control: With the development of automation technology, multi - use cell bioreactors and fermenters will be equipped with more advanced control systems. For example, integrating artificial intelligence and machine learning technologies can realize real - time monitoring and analysis of key parameters such as temperature, pH, and dissolved oxygen, automatically adjust process parameters, optimize the bioprocess, improve production efficiency and product quality, and reduce labor costs and human errors.

Continuous bioprocessing technology: The development of continuous bioprocessing technology enables higher productivity and efficiency. Multi - use cell bioreactors and fermenters that support continuous bioprocessing are expected to be widely adopted. This technology can continuously input raw materials and output products, reducing batch - to - batch variation, improving production stability, and being more suitable for large - scale industrial production.

Integration of new technologies: The integration of new technologies such as microfluidic technology and 3D printing with multi - use cell bioreactors and fermenters is expected to become a development trend. Microfluidic technology can precisely control the micro - environment of cell culture, mimic the in - vivo physiological environment more accurately, and is conducive to improving cell growth and product quality. 3D printing technology can be used to manufacture bioreactor components with complex structures, realizing personalized design and customization of bioreactors.

2.Meeting market and regulatory requirements

Cost - effective solutions: In the context of the growing biopharmaceutical market, there is an increasing demand for cost - effective production processes. Although multi - use cell bioreactors and fermenters have a high initial investment, they can be reused multiple times, which reduces the overall production cost compared to single - use systems. In the case of large - scale production, the cost - saving advantage is more significant. Manufacturers will focus on optimizing the design and manufacturing process of multi - use equipment to further reduce costs and improve economic efficiency.

Stringent regulatory compliance: The biopharmaceutical industry is highly regulated, and multi - use cell bioreactors and fermenters need to comply with strict regulations on product quality, safety, and traceability. Manufacturers will strengthen the development and implementation of cleaning, sterilization, and validation procedures to ensure that the equipment meets regulatory requirements and ensure the quality and safety of products.

Diversification of application fields

3.Expansion of biopharmaceutical applications: The biopharmaceutical industry is developing rapidly, and the demand for multi - use cell bioreactors and fermenters in the production of vaccines, antibodies, and other biologics is increasing. At the same time, with the development of orphan drugs and personalized medicine, these devices will be widely used in the research and production of related drugs. For example, in the production of personalized cell therapies, multi - use bioreactors can provide a stable and controllable environment for culturing patient - specific cells.

Extension to other industries: In addition to the biopharmaceutical industry, multi - use cell bioreactors and fermenters also have application potential in industries such as food, cosmetics, and environmental protection. For example, they can be used to produce food additives, natural cosmetics, and treat industrial wastewater. The expansion of application fields will further promote the development of the multi - use cell bioreactor and fermenter market.

4.Global market expansion

Emerging market development: The biopharmaceutical industries in emerging markets such as Asia - Pacific and South America are developing rapidly, and the demand for multi - use cell bioreactors and fermenters is increasing. These regions have advantages such as low production costs and a large market potential. With the improvement of local technological levels and the expansion of production scales, international manufacturers will increase their investment and layout in emerging markets to promote the growth of the multi - use cell bioreactor and fermenter market in these regions.

Strengthening international cooperation: International cooperation in the biopharmaceutical field is becoming increasingly close. Multi - use cell bioreactor and fermenter manufacturers can expand their market shares through international cooperation and technical exchanges. For example, through cooperation with foreign research institutions and enterprises, they can jointly develop new products and technologies, share market resources, and jointly promote the development of the global multi - use cell bioreactor and fermenter market.

About The Authors

| Miao Yiren - Main analyst for this article Email: miaoyiren@qyresearch.com QYResearch is trusted by over 65,000 clients and has specialized in market research for over 17 years. As a new industry consulting analyst of QYResearch, she specializes in business data analysis, market trend analysis and corporate strategy consulting, and is good at using data analysis tools, such as Python, SPSS, etc., to conduct deep mining of massive business data and provide data support for management decision-making. He has keen market insights and rich project experience in various fields such as finance, manufacturing and agriculture. |

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting (data is widely cited in prospectuses, annual reports and presentations), industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

Contact Us:

If you have any queries regarding this report or if you would like further information, please contact us:

QY Research Inc.

Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United States

E-mail: global@qyresearch.com

Tel: 001-626-842-1666(US) 0086-133 1872 9947(CN)

EN: https://www.qyresearch.com

JP: https://www.qyresearch.co.jp

More Posts

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.